In a significant advancement for tunnel engineering, researchers have developed a novel waterproof-drainage system designed to effectively mitigate water leakage in tunnels. Traditional waterproofing methods have long been plagued by failures, leading to structural deterioration and safety concerns. The new system, based on double-bonded waterproofing materials, promises enhanced performance in preventing water seepage.

Breakthrough in Tunnel Waterproofing Technology

The research team, comprising experts from Central South University, PowerChina ZhongNan Engineering Corporation Limited, Beijing Oriental Yuhong Waterproof Technology Co. Ltd., and Shenzhen University, has published their findings in a study titled “A Novel Tunnel Waterproof-Drainage System Based on Double-Bonded Waterproofing Materials and Its Seepage Characteristics.” This innovative system addresses the limitations of existing drainage techniques used in tunnels.

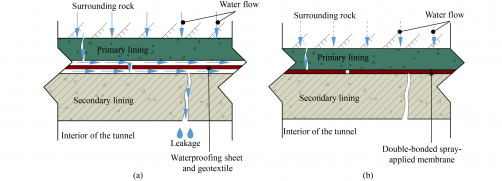

Traditional waterproofing systems typically rely on non-bonded sheets that do not adequately adhere to the primary and secondary linings. This design flaw allows groundwater to flow between layers, resulting in leakage when defects occur. In contrast, the double-bonded spray membrane waterproofing materials proposed in this study provide superior waterproofing and load-bearing capabilities. However, their unique nature has rendered traditional drainage methods ineffective.

Components and Performance of the New System

The newly proposed waterproof-drainage system incorporates a “localized drainage and pressure reduction” strategy. Its design features four key components: a double-bonded spray membrane, an upper circumferential drainage system, a bottom circumferential drainage system, and a longitudinal drainage system.

The waterproof system utilizes a double-bonded spray membrane positioned between the primary and secondary linings, excluding the arch section. The upper circumferential drainage mechanism includes plastic drainage sheets that direct groundwater to longitudinal pipes, ultimately channeling it to a central ditch. In addition, the bottom circumferential drainage system collects surrounding rock groundwater through blind pipes and directs it to the same central ditch.

Numerical simulations conducted as part of the study provided insights into the system’s seepage characteristics. Results indicate that the water pressure on the secondary lining displays distinct distributions, characterized as “mushroom-shaped” in the circumferential direction and “wave-shaped” longitudinally. The maximum recorded pressure was 0.6 MPa, significantly lower than both fully encapsulated waterproofing systems, which reached 1.7 MPa, and traditional drainage systems at 0.86 MPa. This represents a reduction of 65% and 30%, respectively.

Further analysis confirms that the new system effectively reduces static water pressure by at least 40% across various groundwater environments. In ultra-low permeability strata, the reduction can reach approximately 85%. The adaptability of the system is heightened by its design, which allows bottom blind pipes to dominate drainage in high-permeability rock while upper drainage sheets are more effective in low-permeability conditions.

This innovative approach to tunnel waterproofing not only addresses existing challenges but also opens avenues for enhanced safety and performance in tunnel operations. The full text of the research paper is available at https://doi.org/10.1007/s11709-024-1100-4.