A significant breakthrough by researchers at the University of St Andrews has unveiled a method to convert everyday household plastic waste into essential building blocks for anti-cancer medications. This innovative process focuses on recycling polyethylene terephthalate (PET), commonly found in plastic bottles and textiles, paving the way for a new approach in pharmaceutical manufacturing.

Recycling PET Waste into Valuable Pharmaceuticals

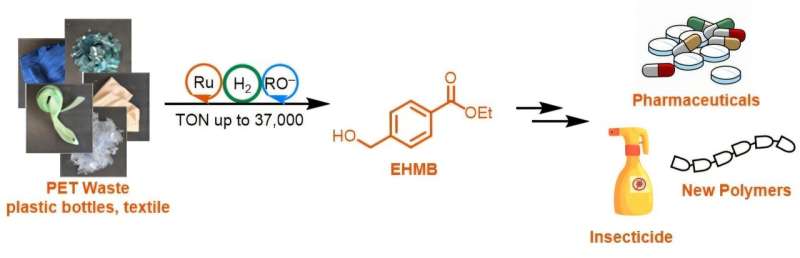

The study, published in Angewandte Chemie International Edition on December 19, 2025, details how PET waste can be recycled through two primary methods: mechanical and chemical. The research team utilized a ruthenium-catalyzed semi-hydrogenation process to efficiently break down the long polymer chains of PET into useful monomers or other chemicals. This transformation yields a valuable compound known as ethyl-4-hydroxymethyl benzoate (EHMB).

EHMB is crucial for synthesizing several important pharmaceutical compounds, including the prominent anti-cancer drug Imatinib and Tranexamic acid, which assists in blood clotting. The current methods for producing these medications typically rely on fossil-derived feedstocks, often involving hazardous reagents that generate significant waste. This research presents a more sustainable alternative, as it not only addresses waste management but also enhances the overall environmental footprint of pharmaceutical production.

Environmental Advantages and Economic Feasibility

The findings suggest that using recycled PET for producing EHMB offers considerable environmental advantages over traditional industrial methods. A comparative hot-spot analysis, conducted as part of a streamlined life cycle assessment, identified critical areas within the production process that contribute to environmental impact, allowing for targeted improvements.

Lead author Dr. Amit Kumar from the School of Chemistry at St Andrews expressed enthusiasm for this discovery. He stated, “We are excited by this discovery, which reimagines PET waste as a promising new feedstock for generating high-value APIs (Active Pharmaceutical Ingredients) and agrochemicals.” Dr. Kumar emphasized the potential of chemical recycling to facilitate a circular economy. He noted that many existing technologies struggle with economic viability. By converting plastic waste into high-value products, this research could significantly accelerate the shift towards sustainable practices.

Professor Evgeny Pidko from TU Delft in the Netherlands, a partner in this research, highlighted the importance of catalyst efficiency in practical applications. He noted, “For catalytic upcycling to become practical, the catalyst must operate efficiently at low loadings and maintain activity over long periods.” The team achieved record turnover numbers of up to 37,000, underlining the importance of understanding catalyst behavior to optimize both durability and efficiency.

Dr. Benjamin Kuehne and Dr. Alexander Dauth from Merck KGaA also contributed to the study, emphasizing the pressing need for innovative and sustainable chemical processes. They pointed out that pharmaceutical manufacturing produces significant waste per kilogram of product, underscoring the urgency for raw materials with reduced environmental impact.

The research from the University of St Andrews marks a substantial advancement in both environmental sustainability and pharmaceutical manufacturing. By transforming plastic waste into valuable chemicals, this initiative not only addresses the growing plastic pollution crisis but also opens new avenues for producing life-saving medications in an eco-friendly manner.