Advancements in orthopedic surgeries have seen a promising development with the introduction of a novel micro-grinding technique aimed at enhancing the safety and efficacy of bone procedures. Researchers from institutions including Qingdao University of Technology, University of Southern California, and University of Sharjah have proposed a method known as ultrasonic vibration-assisted nanoparticle jet mist cooling (U-NJMC). This innovative approach addresses significant challenges faced in traditional micro-grinding techniques, which can lead to thermal damage and complications in postoperative recovery.

Current micro-grinding methods often suffer from inadequate cooling, poor visibility during procedures, and excessive grinding forces. These issues can result in elevated temperatures that are harmful to both bone and surrounding tissues. The study titled “Machinability of ultrasonic vibration-assisted micro-grinding in biological bone using nanolubricant,” conducted by researchers including Yuying YANG, Min YANG, and Changhe LI, explores the effectiveness of U-NJMC in overcoming these limitations.

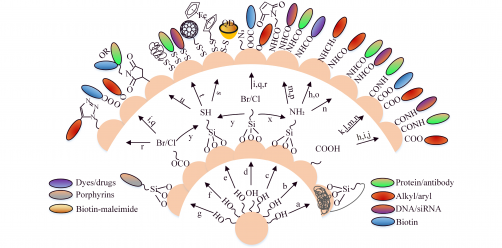

The research utilized fresh bovine tibial dense bone, selected for its mechanical properties that closely resemble those of human bone. The team employed a diamond micro-grinding tool and conducted experiments under six distinct grinding conditions: dry grinding, drip irrigation, ultrasonic vibration (UV), minimum quantity lubrication (MQL), nanoparticle jet mist cooling (NJMC), and U-NJMC. Key metrics such as grinding force, friction coefficient, specific grinding energy, and grinding temperature were meticulously analyzed.

Analyzing the results revealed that the grinding force varied significantly depending on the orientation of the bone tissue. The study found that the section grinding force was the highest, followed by the side and surface forces. Among all six conditions tested, U-NJMC demonstrated superior performance. The minimum normal grinding force recorded was 1.39 N, and the tangential grinding force was 0.32 N, representing reductions of 75.1% and 82.9% compared to traditional dry grinding techniques, respectively.

Additionally, the friction coefficient and specific grinding energy were significantly lower under U-NJMC conditions. The friction coefficient decreased by 31.3% compared to dry grinding, and the specific grinding energy was reduced by an impressive 83.0%. The lowest grinding temperature observed was approximately 26.2 °C, which is 33.5% and 10.0% lower than those recorded during UV and NJMC processes, respectively.

These findings indicate that U-NJMC effectively mitigates the challenges of high grinding force and temperature, making it a promising technique for clinical applications in micro-grinding biological bone. By ensuring better control over the grinding process, this method could significantly enhance surgical outcomes and reduce recovery time for patients.

The full research paper, authored by Yuying YANG, Min YANG, Changhe LI, Runze LI, Zafar SAID, Hafiz Muhammad ALI, and Shubham SHARMA, is available for further reading at the following link: https://doi.org/10.1007/s11465-022-0717-z. This innovative approach underscores the potential of cross-disciplinary research in advancing medical technology and improving patient care.