In a significant advancement for aerospace manufacturing, researchers have developed a new approach to improve the milling process for the nickel-based high-temperature alloy GH4169. This alloy is essential for manufacturing key components of aeroengines due to its outstanding high-temperature strength and resistance to oxidation and corrosion. However, machining GH4169 poses challenges, including high milling temperatures and residual stress during processing.

Traditional machining methods often rely on high-flow cutting fluids, which contribute to environmental pollution and are not utilized efficiently. Moreover, conventional minimum quantity lubrication (MQL) presents issues such as uncontrollable droplet sizes and the potential for harmful fine particles to drift into the air, posing health risks. In contrast, electrostatic atomization minimum quantity lubrication (EMQL) offers a promising alternative, but its effectiveness has not been fully understood, limiting its broader application.

A team of researchers from the School of Mechanical and Automotive Engineering at Qingdao University of Technology and Hanergy Lubrication Technology Co., Ltd. in China, led by Min Yang and Hao Ma, has undertaken a study titled “Force Model in Electrostatic Atomization Minimum Quantity Lubrication Milling GH4169 and Performance Evaluation.”

Key Findings from the Research

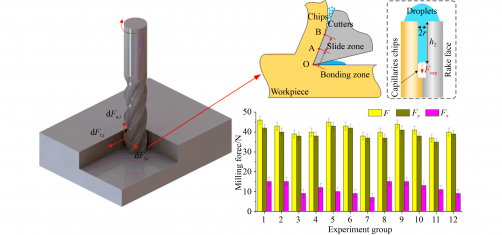

The study initiates by establishing a milling force model that discretizes the helical edge of the end mill into microelements. This model accounts for the tangential, radial, and axial forces of these microelements, ultimately deriving the total cutting force through coordinate transformation and integration. The researchers utilized soybean oil as the lubrication medium and conducted comparative evaluation experiments between EMQL and traditional pneumatic atomization MQL on GH4169.

The results indicate that EMQL significantly enhances milling performance. Compared to conventional MQL, EMQL reduces the milling force by 15.2% to 15.9%, lowers surface roughness by 30.9% to 54.2%, and minimizes the average roughness spacing by 47.4% to 58.3%. Additionally, the friction coefficient decreased by 55%, and cutting specific energy was reduced by 19.6%.

Further analysis was conducted through orthogonal optimization experiments to assess the impact of various parameters, including flow rate, air pressure, voltage, incident angle, elevation angle, and target distance on milling performance. The findings revealed that air pressure has the most substantial influence on milling force and cutting specific energy, contributing 22% to these metrics. In contrast, voltage was found to significantly affect surface roughness, with a contribution rate of 36.71%.

The optimal parameter combination identified for the EMQL process includes a flow rate of 80 mL/h, air pressure of 0.1 MPa, voltage of 30 kV, a nozzle incident angle of 35°, elevation angle of 30°, and a target distance of 40 mm.

Implications for Aerospace Manufacturing

This research provides vital technical support aimed at enhancing the surface integrity of difficult-to-machine aerospace materials during cutting processes. By improving milling efficiency and reducing environmental impact, the study paves the way for more sustainable practices in the aerospace manufacturing sector.

The full text of the paper, “Force Model in Electrostatic Atomization Minimum Quantity Lubrication Milling GH4169 and Performance Evaluation,” is available for further reading at https://doi.org/10.1007/s11465-024-0800-8.