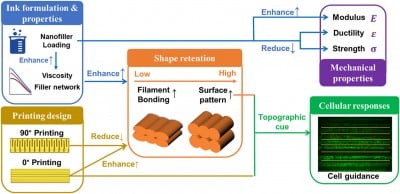

A recent study has revealed significant advancements in the field of bioactive implants through the innovative use of 3D printing technology. Researchers demonstrated how the interplay between ink composition and printing design can influence the structure, strength, and bioactivity of bone implants. By fine-tuning these elements, the team developed implants that effectively promote bone cell growth while ensuring stability, marking a notable step forward in personalized treatment options for bone repair.

The study, published in the *Journal of Biomedical Materials Research* in October 2023, highlights the intricate relationship between the materials used in 3D printing and the design processes involved. By adjusting the composition of the printing ink, researchers were able to create implants tailored to encourage optimal bone integration. This development holds promise for patients requiring customized solutions for bone repair.

Key to the success of these bioactive implants is the ability to manipulate their physical properties. The researchers found that specific combinations of materials not only enhanced the strength of the implants but also increased their bioactivity. This means that the implants can better interact with the surrounding biological environment, fostering an environment conducive to bone cell growth.

The implications of this research extend beyond laboratory settings. As the demand for personalized medical treatments rises, these bioactive implants could lead to more effective surgical outcomes for patients suffering from various bone-related conditions. The ability to create implants that are not only strong but also promote healing represents a significant advancement in medical technology.

In the context of healthcare costs, the development of these advanced implants could potentially reduce the need for additional surgeries and complications associated with traditional bone repair methods. By focusing on individualized treatment, the research aligns with broader trends in healthcare that emphasize tailored medical solutions.

As the field of 3D printing continues to evolve, the findings from this study may pave the way for further innovations in bioactive materials. The ongoing collaboration between materials scientists, biomedical engineers, and healthcare professionals will be essential in translating these advancements into clinical applications.

In conclusion, the research on 3D-printed bioactive implants exemplifies how engineering and medical science can converge to enhance patient care. As the promise of personalized treatments becomes more tangible, the future of bone repair looks brighter, thanks to the innovative approaches being developed by researchers in this field.