The Massachusetts Institute of Technology (MIT) has introduced a new manufacturing education program aimed at enhancing the skills of workers across the United States. Launched this fall, the Technologist Advanced Manufacturing Program (TechAMP) is designed to bridge the gap between traditional roles in manufacturing, such as engineers and technicians, by creating a new category of skilled workers known as technologists. This initiative received funding from the U.S. Department of Defense and aims to boost both individual careers and company productivity.

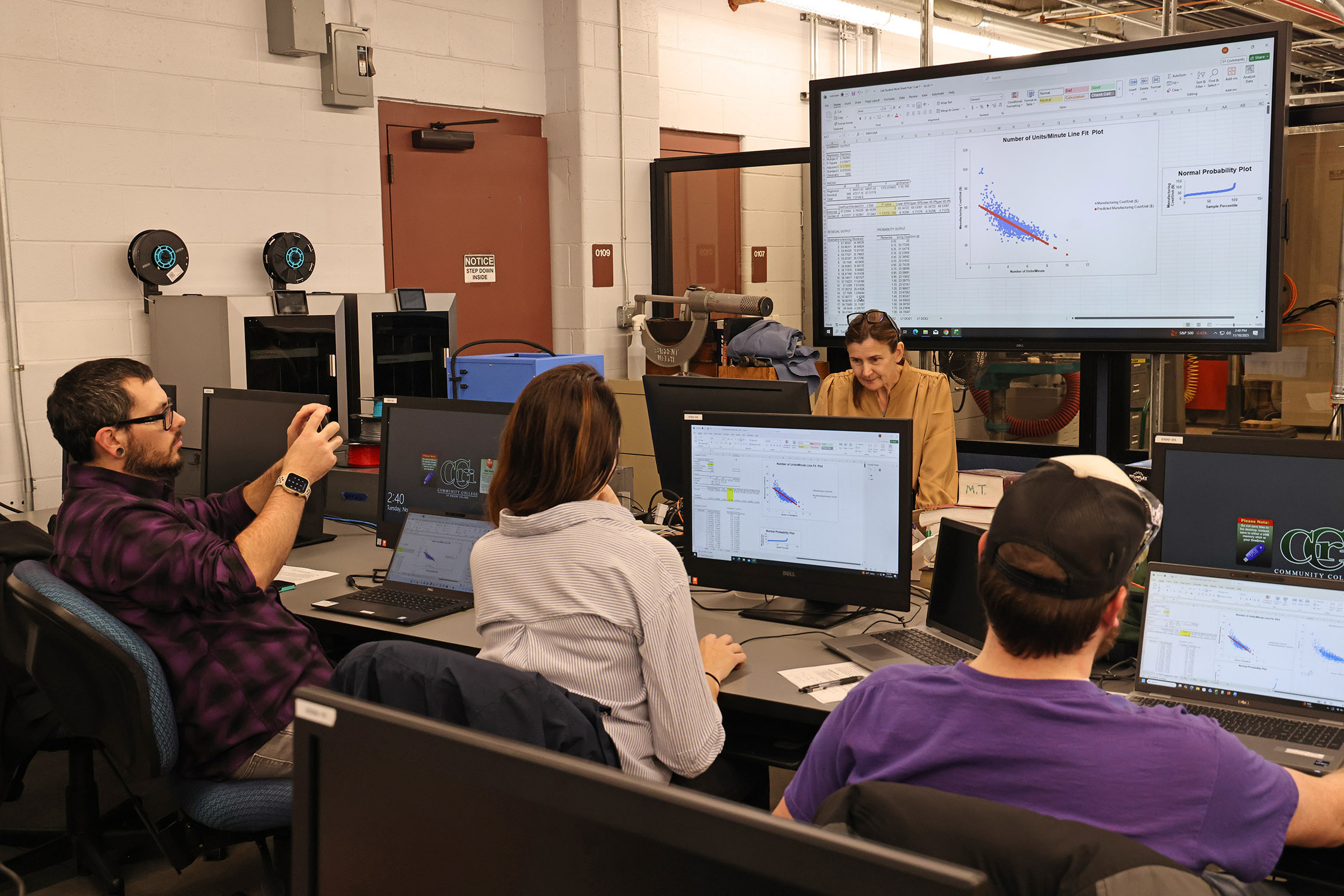

TechAMP is a comprehensive 12-month certificate program that combines in-person lab instruction at various collaborating institutions with online lectures from MIT faculty. The curriculum includes interactive simulations and capstone projects, allowing participants to tackle real manufacturing issues within their companies. By focusing on core manufacturing principles, TechAMP seeks to equip workers with a robust understanding of the industry, ultimately helping firms develop a more skilled workforce.

Program Details and Collaborations

The program is being implemented in partnership with multiple institutions, including the University of Massachusetts at Lowell, Cape Cod Community College, Ohio State University, Community College of Rhode Island, Connecticut Center for Advanced Technology, and the Berkshire Innovation Center in Pittsfield, Massachusetts. Currently, over 70 students are enrolled in the initial cohort of TechAMP.

John Liu, a principal research scientist in MIT’s Department of Mechanical Engineering and co-principal investigator of TechAMP, explained the program’s significance: “We think there’s a gap between the traditional worker categories of engineer and technician, and this technologist training fills it.” Liu emphasized the importance of creating new career pathways that allow workers to understand the entire manufacturing system rather than focusing solely on isolated tasks.

Julie Diop, executive director of MIT’s Initiative for New Manufacturing (INM), highlighted that TechAMP is a key component of a broader effort to rejuvenate U.S. manufacturing. Announced in May 2025, the INM focuses on fostering collaboration between educational institutions and industry to reshape the manufacturing landscape.

Skills Development and Industry Impact

The curriculum revolves around a “hub-and-spoke” model. The core principles, or “hub,” cover essential topics such as manufacturing process controls, systems understanding, leadership skills, and operations management. Six additional areas, known as “spokes,” include mechatronics, automation programming, robotics, machining, digital manufacturing, and design fundamentals. This framework aims to provide a well-rounded education that enables technologists to understand their companies’ operations holistically.

Nicole Swan, an employee at Proterial—a manufacturing firm in Rhode Island—expressed her enthusiasm for the program, stating, “It’s been a confidence booster. This has really shown me so many different opportunities for what I could do in the future, and different avenues that are available.” Such feedback demonstrates the program’s potential to inspire workers and encourage career advancement.

The capstone project component is particularly noteworthy, as it encourages students to analyze challenges within their firms. Ideally, these projects will lead to cost savings or increased value, making it worthwhile for companies to invest in their employees’ education. Diop noted that this could represent a form of direct value capture for the firms involved.

Michael Trotta, CEO of Crystal Engineering, a manufacturer in Newburyport, Massachusetts, commented on the program’s relevance. He remarked, “There are so many manufacturing jobs that don’t need a four-year degree but do require a very high skill level and good communication skills.” Trotta believes that TechAMP represents a logical step toward developing a sustainable workforce capable of adapting to the complexities of modern manufacturing.

As TechAMP continues to evolve, discussions are underway with educational networks in various manufacturing-centric states to explore potential partnerships. The early response has been overwhelmingly positive, with interest coming not only from educational institutions but also from a range of manufacturers eager to engage with MIT’s innovative approach to workforce development.

By redefining the role of technologists in manufacturing, MIT aims to create a pathway that empowers workers and enhances the industry’s perception. As Diop aptly noted, “Manufacturing has had a reputation for dead-end jobs, but if MIT can help break that image by providing a real pathway, it would be meaningful, especially for those without university degrees.” With initiatives like TechAMP, MIT is positioning itself at the forefront of a transformative movement in manufacturing education.