A new facility, showcased by inventor Nature Jab, is harnessing solar power to convert scrap plastic into fuel. This innovative pyrolysis machine, described as the world’s most complex handmade pyrolysis reactor, utilizes advanced technology to decompose plastic waste into natural gas and petroleum.

The facility operates entirely on solar energy, featuring a 100 kWh Komodo commercial power tank and approximately 20 solar panels that generate between eight to nine kilowatts of power. This sustainable approach not only addresses plastic waste but also provides a renewable energy source for the conversion process.

How the Pyrolysis Process Works

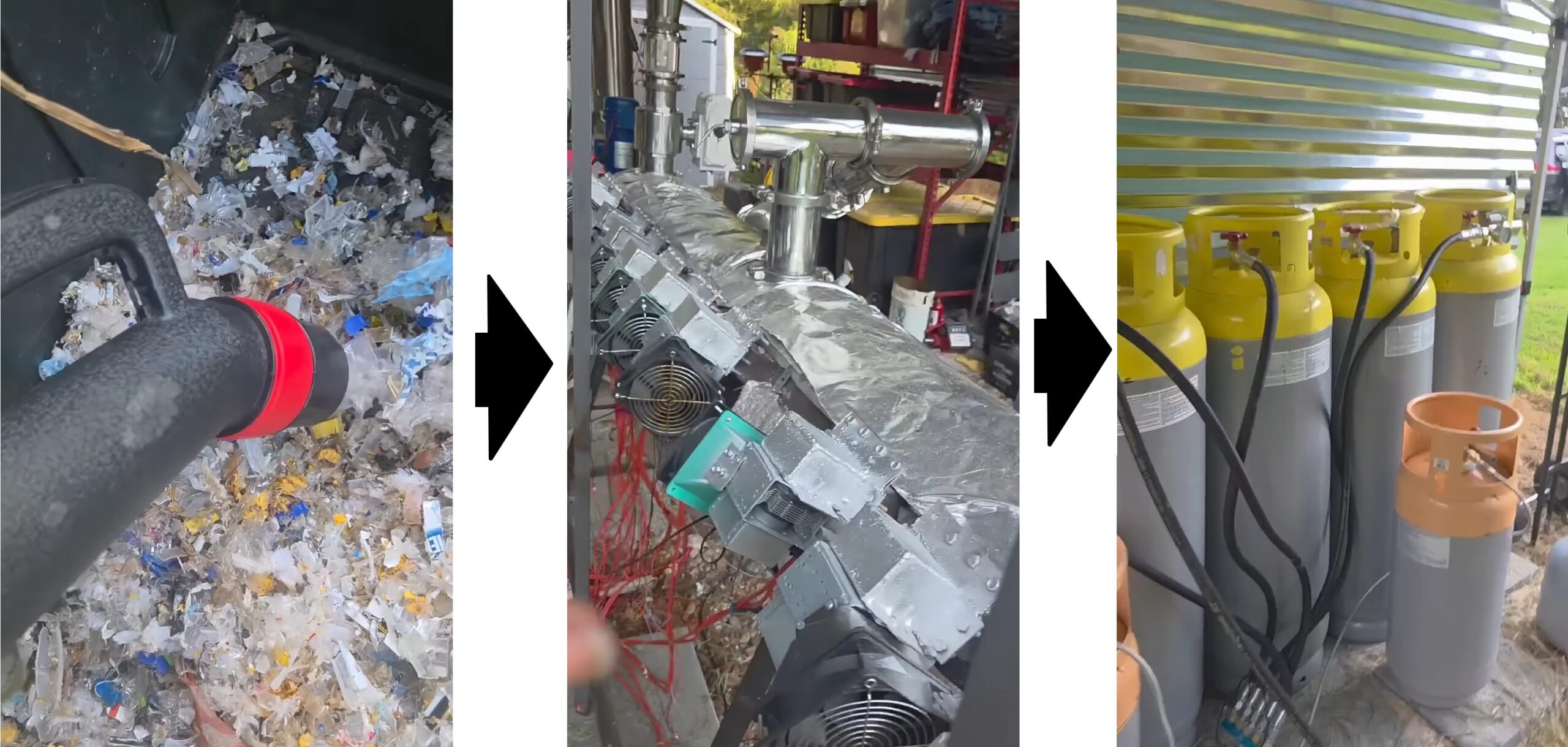

Pyrolysis is a thermal decomposition process where heat is applied to organic materials in an inert environment, such as a vacuum. In this case, scrap plastic is decomposed, returning to its original components: natural gas and petroleum. The process begins with loading the plastic into the machine via a vacuum pump connected to a flexible tube.

Once inside, the plastic is transported to the main vacuum chamber, where it is subjected to the heat generated by eight active magnetrons, similar to those found in microwave ovens. Due to the absence of air in the chamber, the plastic does not ignite; instead, it melts and vaporizes. This vapor is subsequently cooled through a dephlegmator, resulting in the formation of crude oil and natural gas, which are collected separately for future use and processing.

The facility’s design is a testament to innovation in waste management and renewable energy. By converting plastic waste into usable fuel, it addresses two significant global challenges: plastic pollution and energy sustainability.

For those interested in further exploring the potential of pyrolysis, the concept of methane pyrolysis presents another avenue, producing green hydrogen without carbon emissions. This facility represents a promising step forward in the quest for environmentally friendly solutions to energy and waste management.