General Motors (GM) is transforming its vehicle production process through the implementation of advanced virtual reality (VR) technology at its Virtual Reality Assembly Center in Warren, Michigan. This innovative facility has already identified and rectified 494 issues in vehicle design without the need for physical prototypes.

The VR assembly center allows GM employees to collaborate virtually, enabling them to address manufacturing challenges in real time. This approach has significantly reduced the need for travel, allowing employees from various locations to solve complex problems as if they were in the same room. According to Max Sikorski, head of GM’s VR team, the technology is more effective and cost-efficient than traditional methods such as video conferencing.

Enhancing Pre-Production Processes

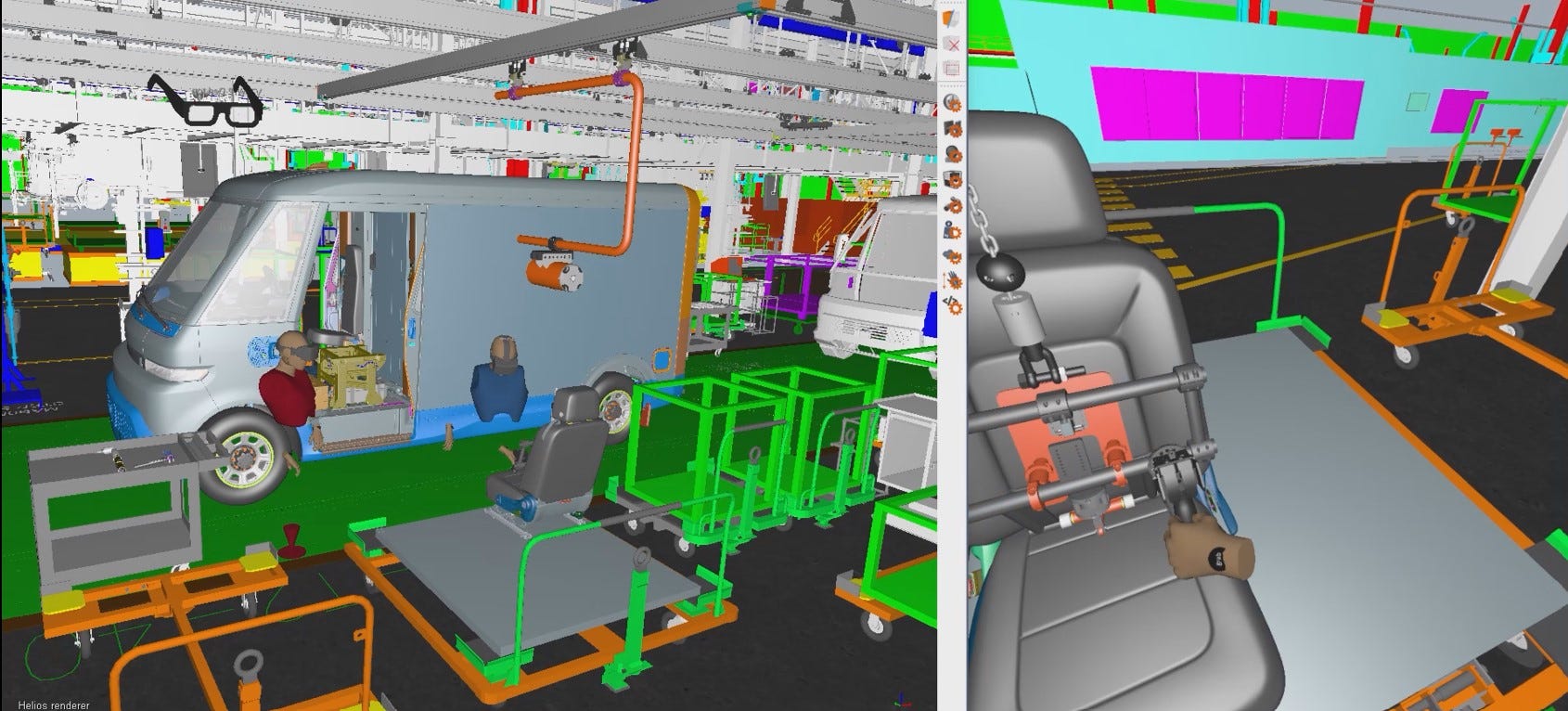

Since its launch in 2022, the VR program has hosted six major build events this year, engaging manufacturing employees from across GM’s operations. Workers log into virtual plants that are meticulously mapped, complete with realistic details, to collaborate on vehicle designs long before they are produced. Sikorski emphasized the effectiveness of this approach by stating, “When we do a build for Spring Hill (Tennessee), it’s run here. They don’t have to set up any of the simulations — they have the same equipment.”

This method allows for the identification of issues early in the development process, ultimately saving both time and money. “We found 494 issues this year without ever touching a real vehicle,” Sikorski explained. “If we catch an issue now, it’s not going to be an issue later.” The elimination of physical prototypes can save GM up to $100,000 per vehicle.

During a recent visit on September 8, 2023, large black dividers concealed most of the testing space, with only a small area visible where the VR simulations take place. Sikorski noted the importance of confidentiality, stating, “We work on everything several years before it hits even real prototypes.”

Integration of AI in Vehicle Design

GM is not only leveraging VR but also integrating artificial intelligence (AI) into its pre-production simulations. This combination enhances the efficiency of the manufacturing process by utilizing historical data to inform decisions. Dwaine Carswell, a virtual assembly inspector with over 15 years of experience, highlights the importance of ergonomic assessments in the VR environment. The technology tracks movements and alerts users to potentially harmful postures, helping to prevent workplace injuries.

Sikorski indicated that the VR program has already tracked and resolved over 50 ergonomic-related safety issues. By using Xsens suits for motion capture, the program creates a digital representation of workers, allowing for real-time feedback on assembly techniques. “We do exploratory VR, which means we build the entirety of the vehicle to get feedback years in advance,” Sikorski stated.

As the automotive industry continues to evolve, GM’s commitment to embracing cutting-edge technologies like VR and AI positions the company at the forefront of vehicle production innovation. The VR assembly center not only streamlines operations but also improves safety and efficiency across the board.

In conclusion, General Motors is pioneering a new era in vehicle manufacturing by utilizing advanced virtual reality and artificial intelligence technologies. This initiative not only enhances collaboration among its workforce but also significantly reduces costs and improves safety, ultimately reshaping the future of automotive production.