Engineers at McGill University have created groundbreaking materials that could revolutionize the field of soft robotics. These ultra-thin, flexible materials, derived from graphene oxide, can move, fold, and reshape themselves, offering new capabilities for adaptive devices. The research, led by Hamid Akbarzadeh from the Department of Bioresource Engineering and Marta Cerruti from the Department of Mining and Materials Engineering, addresses long-standing limitations in the practical application of graphene oxide in robotics.

The primary challenge has been the brittleness of traditional graphene oxide films, which hinders their manufacturing and limits their ability to produce complex motion. According to Cerruti, “Graphene oxide films are highly promising for next-generation soft robots and adaptive actuators, yet their real-world deployment remains limited because they are brittle, challenging to manufacture at scale and unable to generate complex or programmable motion.”

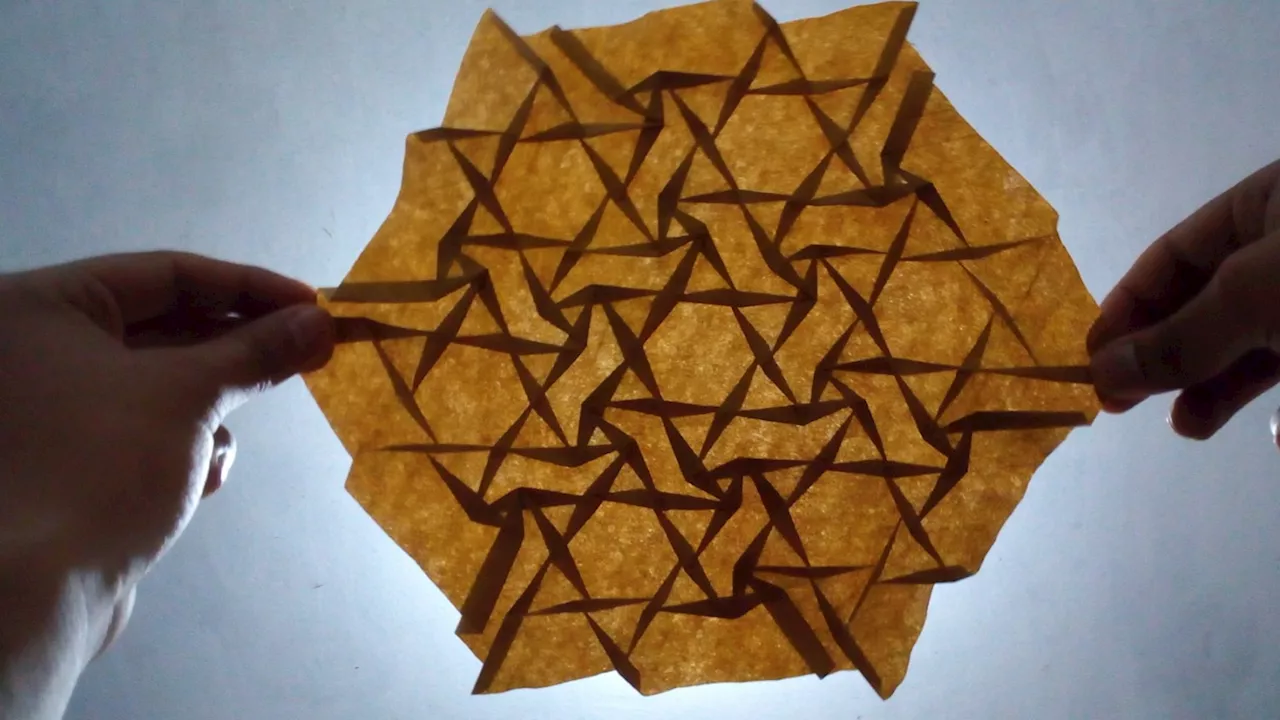

To overcome these hurdles, the research team developed graphene oxide films that maintain both strength and flexibility. These paper-like sheets can be folded into structures reminiscent of origami without cracking, thus ensuring mechanical stability. This adaptability makes them ideal for soft robots that need to operate safely around humans, eliminating the risks associated with rigid components and heavy motors.

Innovative Motion and Control Mechanisms

The researchers demonstrated the capabilities of these folded graphene oxide structures by programming them to respond to environmental triggers. One notable experiment showcased how the origami-like structures react to humidity. When exposed to moisture, the shapes expand, and as the material dries, they contract again. This reversible motion allows the material to function as an actuator powered solely by environmental conditions.

In another innovative approach, the team embedded tiny magnetic particles within similar graphene oxide origami structures. This modification enables remote control of the material using an external magnetic field, allowing for steering and movement without physical connections. Such versatility could lead to applications in diverse environments, from medical tools navigating delicate internal spaces to smart packaging that responds to humidity or temperature changes.

Beyond movement, the electrical conductivity of the graphene oxide layers changes as the material bends or folds. This unique property allows the structures to sense their own motion, effectively acting as both an actuator and a sensor. Akbarzadeh noted, “These advances enable robust, reconfigurable and multifunctional GO metamaterials capable of complex motion, user-defined shape changes, integrated sensing and real-time feedback, marking the emergence of the first reconfigurable sensoriactuator metamaterials.”

Applications and Future Prospects

The combination of motion, sensing, and reconfigurability positions these graphene oxide origami materials as foundational elements for a new class of soft machines. Potential applications include medical devices that navigate the human body with gentleness, wearable systems that adapt to the contours of the skin, and small robots designed for confined or sensitive environments.

Crucially, the research also indicates that these materials can be manufactured at scale, addressing significant barriers that have previously impeded advancements in soft robotics. By simplifying the design to rely on folded sheets rather than complex assemblies, the approach offers a practical pathway for real-world deployment.

The findings from this research have been published in the journals Materials Horizons and Advanced Science. As the field of soft robotics continues to evolve, these innovations in graphene oxide materials could play a pivotal role in developing devices that are safer, more responsive, and better suited for a variety of applications.