Researchers at the Eindhoven University of Technology (TU/e) have made significant strides in revolutionizing plastic recycling by utilizing LED light. Led by Assistant Professor Fabian Eisenreich, this groundbreaking work involves creating and breaking down a new class of high-performance plastics, paving the way for a truly sustainable recycling process. The findings, published on August 15, 2025, in the Rising Stars edition of Advanced Materials, could fundamentally alter how plastic waste is managed globally.

Eisenreich describes his team as “molecular designers,” focusing their efforts on what they term “design for recycling.” Their research aims to develop new polymers that facilitate innovative recycling strategies while minimizing waste and avoiding toxic substances. Such an approach keeps the entire recycling process sustainable, addressing a critical need as plastic waste continues to accumulate worldwide.

Plastics traditionally consist of moldable polymer chains, but conventional recycling methods—primarily heating, melting, and reshaping—often degrade the quality of these chains over time. This deterioration limits the number of times plastics can be recycled, necessitating the production of new materials eventually. In contrast, Eisenreich advocates for chemical closed-loop recycling, which allows polymer chains to be selectively broken down into their original building blocks. These building blocks can then be reused to create the same polymer with identical properties.

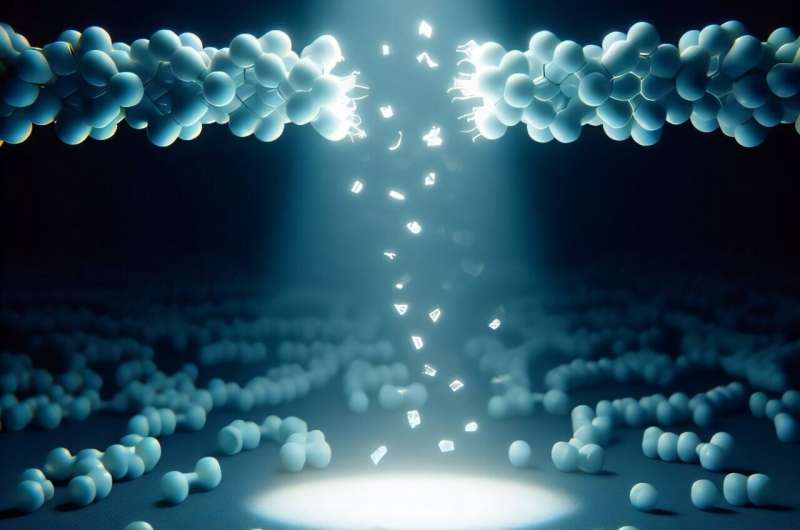

Eisenreich’s research specifically focuses on photochemical recycling, which employs LED light to achieve this process. While making polymers with light is relatively straightforward, the challenge lies in using light to selectively break stable chemical bonds within the polymer. Recently, Eisenreich and third-year Ph.D. candidate Ahsen Sare Yalin successfully demonstrated this capability in the lab, marking a significant advancement in sustainable chemistry.

“This breakthrough can reshape the way we deal with plastic waste in the future,” Eisenreich states. Currently, their designer polymer is tailored for specialized applications, such as recyclable adhesives that bond effectively to glass and other plastics. As research progresses, the potential applications for this technology are expected to expand.

Eisenreich’s work extends into other areas, including developing 3D printing techniques for recyclable polymers using light. This process involves starting with a liquid material that solidifies upon exposure to light, allowing for the production of complex 3D objects. Ultimately, Eisenreich envisions a future where traditional plastics can be photochemically recycled using only sunlight, eliminating the need for additional energy sources.

This innovative approach not only highlights the ongoing transformation in plastic recycling but also represents a broader movement within the field of chemistry. “This is not just a new material. It’s a new way forward,” Eisenreich concludes, emphasizing the potential impact of their work on sustainable practices.

For further details, see the research by Ahsen Sare Yalin et al., titled “A Light-Driven Closed-Loop Chemical Recycling System for Polypinacols,” published in Advanced Materials. The DOI for this publication is 10.1002/adma.202506733.